The impurities and classification of semiconductors are briefly introduced below:

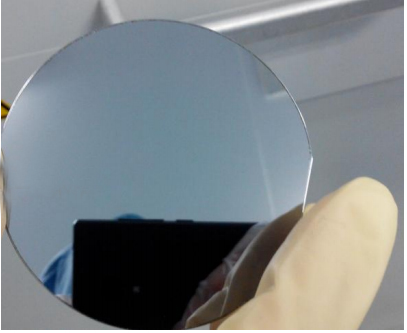

Semiconductor manufacturing requires the participation of some organic and inorganic substances. In addition, since the process is always carried out by people in the purification room, the semiconductor wafer will inevitably be polluted by various impurities. According to the sources and properties of pollutants, they can be roughly divided into four categories: particles, organic matter, metal ions and oxides.

1.1 particles:

The particles are mainly some polymers, photoresists and etching impurities. This pollutant is usually adsorbed on the wafer surface, which affects the geometric formation and electrical parameters of the device lithography process. The removal method of such pollutants is mainly to clean the particles by physical or chemical methods, gradually reduce the contact area between the particles and the wafer surface, and then remove them.

1.2 organic matter:

Organic impurities come from a wide range of sources, such as human skin grease, bacteria, engine oil, vacuum grease, photoresist, cleaning solvent, etc. Such pollutants usually form an organic film on the wafer surface to prevent the cleaning solution from reaching the wafer surface, resulting in incomplete wafer surface cleaning, so that the metal impurities and other pollutants on the cleaned wafer surface remain intact. The removal of such pollutants is usually carried out at the beginning of the cleaning process, mainly using sulfuric acid and hydrogen peroxide.

1.3 metal:

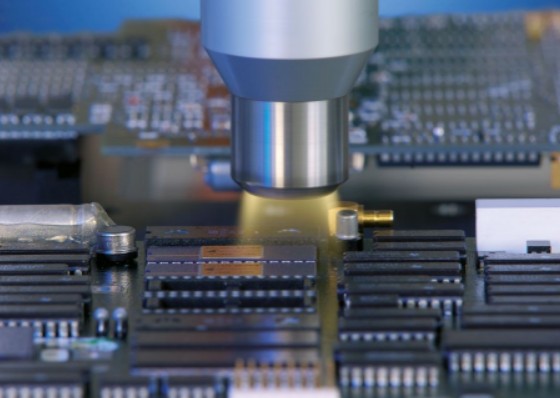

Common metal impurities in semiconductor technology include iron, copper, aluminum, chromium, tungsten, titanium, sodium, potassium, lithium, etc. The sources of these impurities mainly include various containers, pipes, chemical reagents and various metal pollution in the process of semiconductor wafer processing. Chemical methods are often used to remove such impurities. The cleaning solution prepared by various reagents and chemicals reacts with metal ions to form metal ion complexes, which are separated from the wafer surface.

1.4 oxides:

The surface of semiconductor wafer exposed to oxygen and water will form a natural oxide layer. This oxide film not only hinders many steps of semiconductor manufacturing, but also contains some metal impurities, which will be transferred to the wafer under certain conditions to form electrical defects. The removal of this oxide film is usually completed by soaking in dilute hydrofluoric acid.