Online PCBA Cleaning Machine HJS-7800

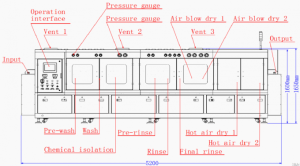

HJS-7800, a 300L liquid tank 3 stages of liquid wash and 3 stages of DI water rinse aqueous cleaning system. It is in-line, high quality, smaller footprint, batch cleaning machine.

HJS-7800 is a powerful PCBA cleaning machine which can clean flux residuals, solder balls and particles on assembly PCBA, such as: rosin flux, water-soluble flux, non-clean flux, solder paste and other organic and inorganic contaminations.

HJS-7800, It is in-line, high quality, smaller footprint, batch cleaning machine.

HJS-7800 is a powerful PCBA cleaning machine which can clean flux residuals, soder balls and particles on assembly PCBA, such as: rosin flux, water-soluble flux, non-clean flux, solder paste and other organic and inorganic contaminations.

Powerful process: Pre-wash+Wash+ Chemical isolation+ Pre-rinse+ Rinse+Final rinse+ Air blow dry+ Hot air dry1+ Hot air dry2. It can use to clean almost all kinds of PCBA.

Machine advantages:

1. Big quantity PCBA in line cleaning system.

2. Large amount liquid spray wash method, super wash result. Thoroughly clean water-sular solder paste flux and non-clean solder paste flux on SMT or THT PCBA after welding.

3. Wash sections + DI water rinse section+ Air blow section +2 hot air dry sections.

4. Liquid and fresh DI water supply automatically, post-section DI water overflow to the previous-section to renew DI water.

5. Up/down spray system on wash and rinse sections.

6. Liquid and DI water spray pressure can be adjusted for different PCBA cleaning requirements.

7. Standard equipped with Resistivity monitoring system, resistivity range 0~18 MΩ.

8. Air knives blow dry+ 2 section hot air dry system.

9. SUS304 stainless PCB flat conveyor net system.

10. PLC control system, English operation interface, easy operation.

11.Many optional functions available.

12. Total SUS304 structure, Acid and Alkali corrosion resistance.

Machine Spec:

|

S/N |

Item |

HJS-7800 Spec |

|

1 |

conveyor net |

500mm |

|

2 |

conveyor speed |

0.1~1.5m/min |

|

3 |

conveyor height |

900±50mm |

|

4 |

conveyor direction |

Left to Right |

|

5 |

PCB size |

L400*W500mm as max |

|

6 |

PCB height |

100mm as max(with component) |

|

7 |

wash tank capacity |

300L |

|

8 |

rinse tank capacity |

40L+120L+30L |

|

9 |

DI water consumption |

400~1000L/H |

|

10 |

exhausted air |

42m³ |

|

11 |

electric control |

PLC+TP |

|

12 |

Resistivity range |

0~18MΩ |

|

13 |

PH range |

0~14 |

|

14 |

air supply |

0.5Mpa |

|

15 |

power supply |

AC380V,50/60HZ, 3P,110KW |

|

16 |

machine size |

L5200*W1800*H1650mm |

|

17 |

machine weight |

2600KG |

Customer Question & Answer

Q1: What kind of PCBA can HJS-7800 clean?

A1: HJS-7800 is a 5200mm long machine, it has 1x600mm wash section with 2×8 spray rods. Normally, it can clean all PCBA by adjusting conveyor speed. For most precise PCBA, it need to adjust conveyor speed to 0.2m/min; Normally it can set to 0.3~0.4m/min.

Q2: Why is it 110KW?

A2: in wash section, it has 2x12KW heater; in pre-rinse section, it has 1x12KW heater; in Rinse section, it has 2x12KW heater; in hot air dry section, it has 2×7.5KW heater, and we also have air blowers, electric pumps.

Q3: What is the liquid temperature and DI water temperature?

A3: liquid temperature can heat to 80℃; DI water can heat to 60℃.

Q4: What is the liquid consumption per hour?

A4: It depends on liquid itself and temperature, we install liquid cool condenser, normally 5~15L/ Hour.